Difference between Conventional Earthing and Chemical Earthing

For a very long, conventional earthing or salt charcoal earthing have been in use for electrical safety in the residential and industrial sector. But conventional earthing had its problems i.e lower life due to salt induced corrosion and very high requirements of water. Let us discuss these problems one by one:

* Corrosion: The sodium salts used for earthing corrode the plate heavily and more so on its terminal. Though the salt is leached out with time with rainy water, till such time, the useful life of the earthing is seriously impaired.

* High requirement of water over the life: The salt is leached out with time, and only loose coal is available surrounding the plate with time. The lumped coal in loose is not in proper contact with the metallic surface to dissipate the fault current effectively. However, with the electrolytic environment of water surrounding the plate the surrounding earth connects with the plate and receives the fault current. However, it makes the earthing unpredictable and unreliable.

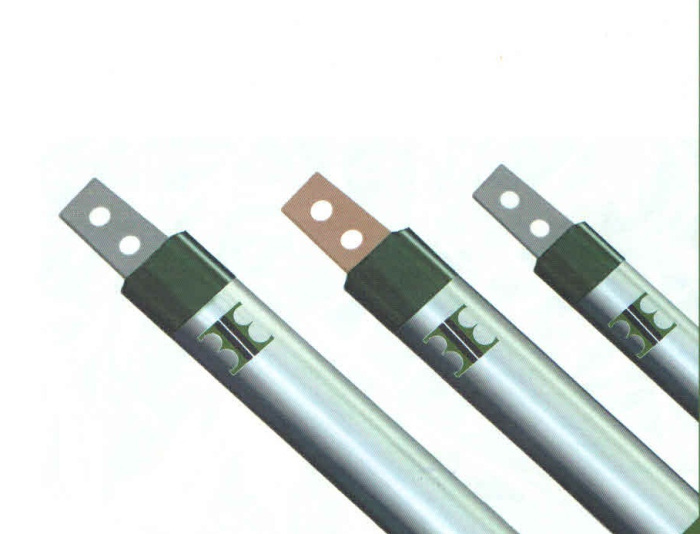

The research by scholars in the field by scientists shows, Only one dimension of the electrode improved performance almost linearly and instead of plate, pipe earthing is more effective. The surrounding soil is in better contact with earthing conductor surface. The earth enhancing compounds also called as backfill compounds help to retain moisture for longer time and create a better contact between surrounding soil and metallic surface. However, the ineffective or poor backfill compound can do more harm if not having desirable properties. So, the performance of the chemical earthing depends upon the manufacturer of Chemical earthing as the Chemical Earthing is only as good as the backfill compound is effective.